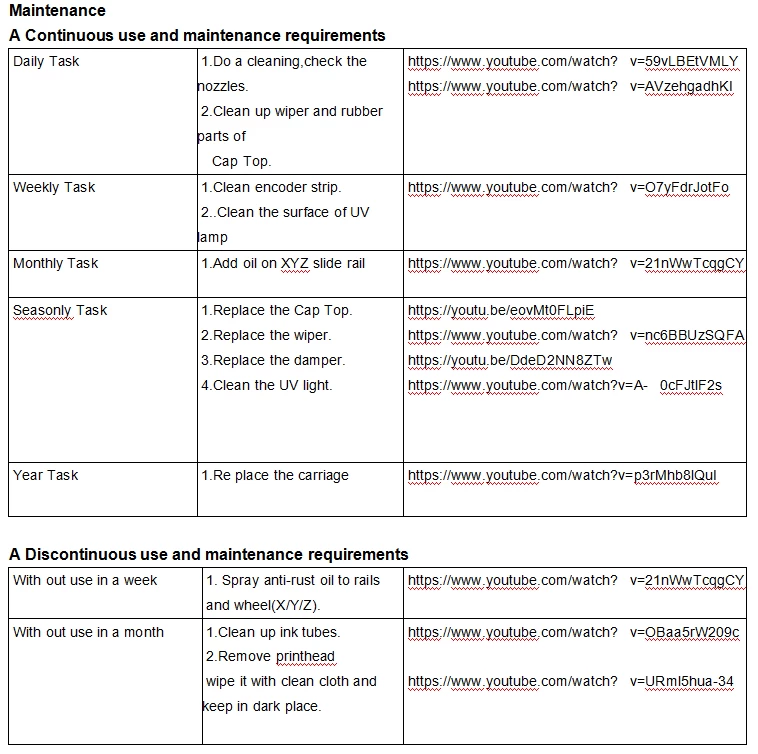

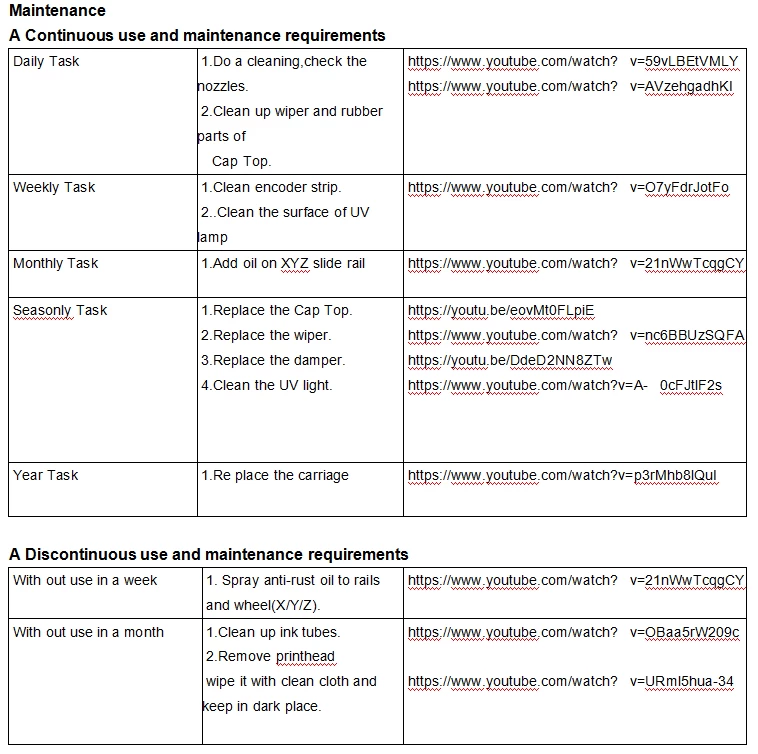

Tell you how to from three aspects for maintenance UV printing in discontinuous or continuous use

Apex Marketing

2018-02-06 18:00:22

As a owner, we hope our UV machine printing has a longer service life and want them can help our customer to earn money as more as possible and. In addition to depending on the original quality of the machine, the latter part of maintenance of the printer also has a great relationship. To achieve long-term excellent printing, UV printing maintenance should include the following aspect.

How to Maintain the printer head

1. If often printing, please do a cleaning and make a nuzzle test everyday to make sure the uv printer head is in good condition.

2. If less printing, please do cleaning three times every three days and make a nuzzle test to make sure the uv printer head is in good condition.

3. If not use the machine over 2 weeks, customers should remove the printer head and use the cleaning liquid to clean the print head and pack the printer head well. And stock it in the dark environment.

4. If the nozzle test is bad, please check the trouble shooting in the user manual, or contact local agent for help.

2. UV flatbed printer ink road maintenance

During long periods of use, UV ink will slowly precipitate a variety of impurities in the ink tube. Usually, it is suggested to replace a set of new ink tube every six months or so.

3. Guide rail maintenance

It is recommended to wipe the lead rail with a lubricant oil every two months to achieve lubrication and maintenance. For one thing, it can reduce running noise. For another, it can reduce the wear and tear caused by friction.

4. Grating ruler maintenance

It requires the technician to use a non-woven dipped in a little alcohol to slowly wipe the surface of the grating ruler, so as to remove the dust and other particles. (Recommended once a month)

5. UV printing platform and surface cleaning

In daily use, regularly remove the the residual ink on the platform and the dust on the printer body with alcohol and non-woven cloth.

6. The surrounding environment cleaning

If there is two much dust in the air floating in the substrate surface, it will directly affect the printing effect, and there may be impurity dots or pattern off or fade. Therefore, daily cleaning and ventilation is particularly important.

1. If often printing, please do a cleaning and make a nuzzle test everyday to make sure the uv printer head is in good condition.

2. If less printing, please do cleaning three times every three days and make a nuzzle test to make sure the uv printer head is in good condition.

3. If not use the machine over 2 weeks, customers should remove the printer head and use the cleaning liquid to clean the print head and pack the printer head well. And stock it in the dark environment.

4. If the nozzle test is bad, please check the trouble shooting in the user manual, or contact local agent for help.

2. UV flatbed printer ink road maintenance

During long periods of use, UV ink will slowly precipitate a variety of impurities in the ink tube. Usually, it is suggested to replace a set of new ink tube every six months or so.

3. Guide rail maintenance

It is recommended to wipe the lead rail with a lubricant oil every two months to achieve lubrication and maintenance. For one thing, it can reduce running noise. For another, it can reduce the wear and tear caused by friction.

4. Grating ruler maintenance

It requires the technician to use a non-woven dipped in a little alcohol to slowly wipe the surface of the grating ruler, so as to remove the dust and other particles. (Recommended once a month)

5. UV printing platform and surface cleaning

In daily use, regularly remove the the residual ink on the platform and the dust on the printer body with alcohol and non-woven cloth.

6. The surrounding environment cleaning

If there is two much dust in the air floating in the substrate surface, it will directly affect the printing effect, and there may be impurity dots or pattern off or fade. Therefore, daily cleaning and ventilation is particularly important.

If there is a “Apex” brand on your UV printer, as long as you do good job in routine maintenance work, it is okay to keep high-quality printing and prolong service time.