UV LED Lamp Technology

UV LED Lamp Technology

An LED printer is a type of computer printer similar to laser printer. LED technology uses a light-emitting diode array as a light source in the printhead instead of the laser used in laser printers and, more generally, in the xerography process. The LED bar pulse-flashes across the entire page width and creates the image on the print drum or belt as it moves past.

LEDs are more efficient and reliable than conventional laser printers, since they have fewer moving parts, allowing for less mechanical wear. Depending on design, LED printers can have faster rates of print than some laser-based designs, and are generally cheaper to manufacture. In contrast to LED printers, laser printers require combinations of rotating mirrors and lenses that must remain in alignment throughout their use. The LED printhead has no moving parts.

LEDs are more efficient and reliable than conventional laser printers, since they have fewer moving parts, allowing for less mechanical wear. Depending on design, LED printers can have faster rates of print than some laser-based designs, and are generally cheaper to manufacture. In contrast to LED printers, laser printers require combinations of rotating mirrors and lenses that must remain in alignment throughout their use. The LED printhead has no moving parts.

UV-LED printer technologies refer to a non-impact, inkjet printing technique that instantly cures jetted ink droplets directly onto the printable substrate. The UV-LED lamp that houses the LEDs emit energy onto the specially formulated UV-LED ink, which contains photoinitiators and are reactive to the energy emitted by the UV-LED lamp.

UV-LED printer technologies refer to a non-impact, inkjet printing technique that instantly cures jetted ink droplets directly onto the printable substrate. The UV-LED lamp that houses the LEDs emit energy onto the specially formulated UV-LED ink, which contains photoinitiators and are reactive to the energy emitted by the UV-LED lamp.

Features:

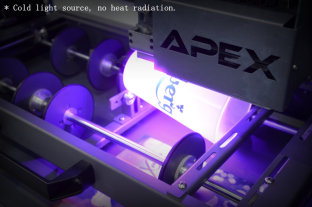

1. Cold light source, no heat radiation, suitable for bonding heat-sensitive material

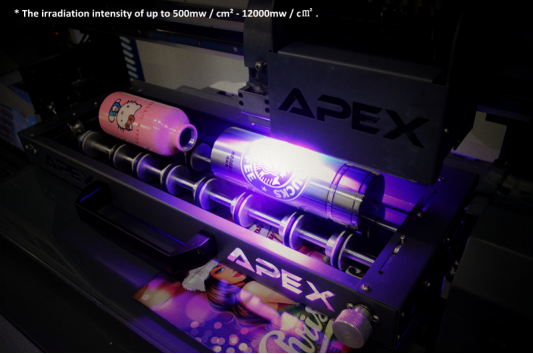

2. Instant open / off, without preheating, the irradiation intensity of up to 500mw / cm² - 12000mw / c㎡ more

3. Compact, so that the device can easily be integrated into fully automated production lines and equipment

4. UV LED no infrared radiation, no harmful gases, in line with ROHS standards. Compared with the traditional mercury lamp safer, more environmentally friendly

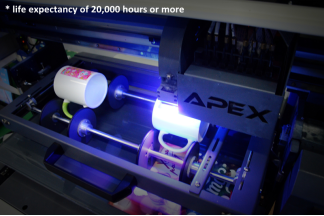

5. Life expectancy of 20,000 hours or more, can significantly reduce operating costs and maintenance time

6. Connect the cable line is resistant to bending, freely mounted on a movable section, repeatedly moved.