What is UV Varnish

UV Varnishing

Also called UV coating, UV varnishing is a process for achieving a thicker and even more striking type of coating on the printed box surface. The printed color appears noticeably richer and vibrant. It also adds the benefit of the fast drying of print on the production line due to the ultra-violet drying process.

The UV varnishing divided into 2 types, all-over UV varnishing and spot UV varnishing

Varnishing TypesAccording to the printing surface gloss level, the varnishing is divided into 4 types, glossy varnishing, matte varnishing and satin varnishing.

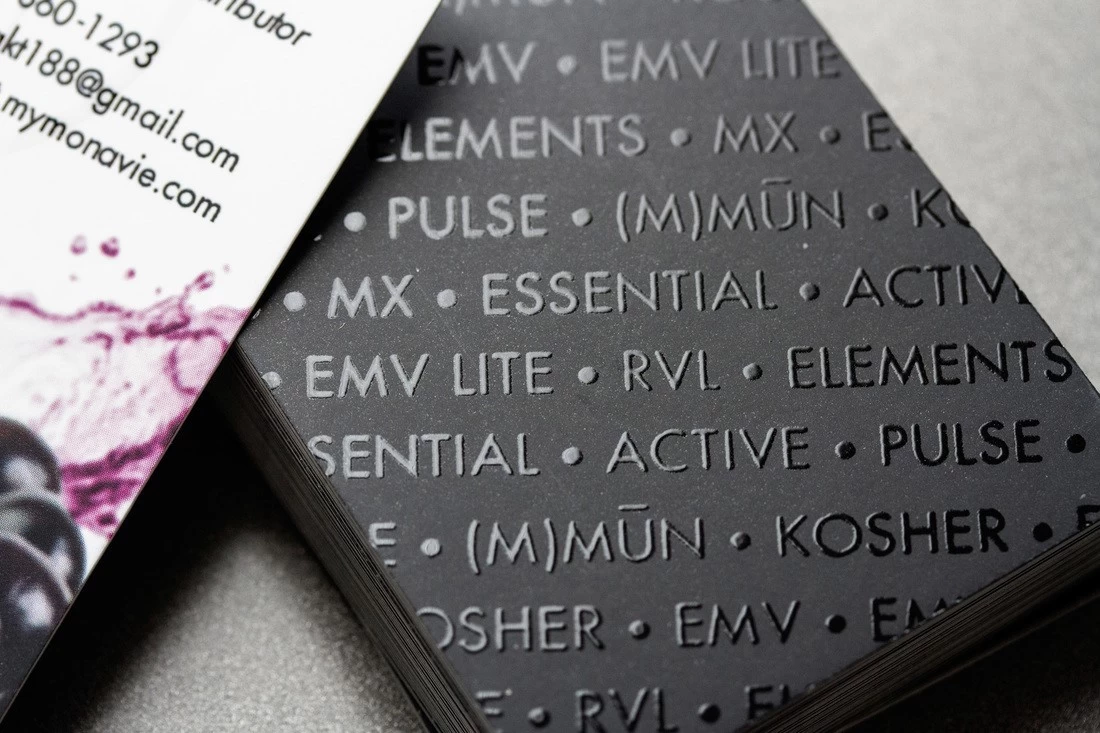

Glossy VarnishingWith the glossy varnish, the printed box surface is smooth, shiny and glossy. In the sunshine, the surface reflects light quite efficiently. Therefore, a glossy varnished printed box usually has the very bright and lustrous color.

A matte varnish gives the printed box a non-glossy, smooth even surface free from shine. This matte finish on the printed box adds to the feeling of luxury. It is the most popular finish used in the luxury packaging of the cosmetics and jewelry products and etc when the seller wants to impart a luxury quality feel to the potential customers.