- Latest News

-

Introducing the APEX UV 6090 Printer with i3200 Printhead: The Ultimate Solution for Versatile and High-Quality Printing

Microtec UV 6090 Flatbed Printer is equipped with the powerful i3200 printhead, offering high-precision printing on diverse materials such as acrylic, metal, glass, and plastic. This 60x90cm UV flatbed printer is ideal for signage, packaging, and promotional items. Its UV-curing technology ensures fast-drying, long-lasting prints with superior quality. Perfect for businesses looking to scale production with versatility and durability.Maximizing Your DTF Printer's Performance: Precautions and Maintenance Tips for Print Heads

Maintaining Peak Performance: Precautions and Maintenance for DTF Printers with Epson i3200 Printer HeadsWhat's DTF? What's the advantages of DTF printing compared with sublimation printing?

Multicolor 300mm A3 DTF Printing System With Double XP600 Print Head, Microtec DTF printer can produce high-quality prints with a range of colors, gradients, and photographic images. It can be used to print designs on a wide range of materials, including textiles such as t-shirts, hoodies, and bags, jeans, hat etc.APEX new arrival A3 size desktop mini UV printer

Industrial Printer-APEX largest UV2513 with Toshiba head

Impressive Versatility On Materials Up To 750mm in Height

The advantages of APEX UV Printer

How to choose 60*90cm UV printer?

Christmas Promotion-How to get APEX free ink

APEX RH series printer can print on uneven surface

- Subscribe

-

Get email updates on new products

- Follow us

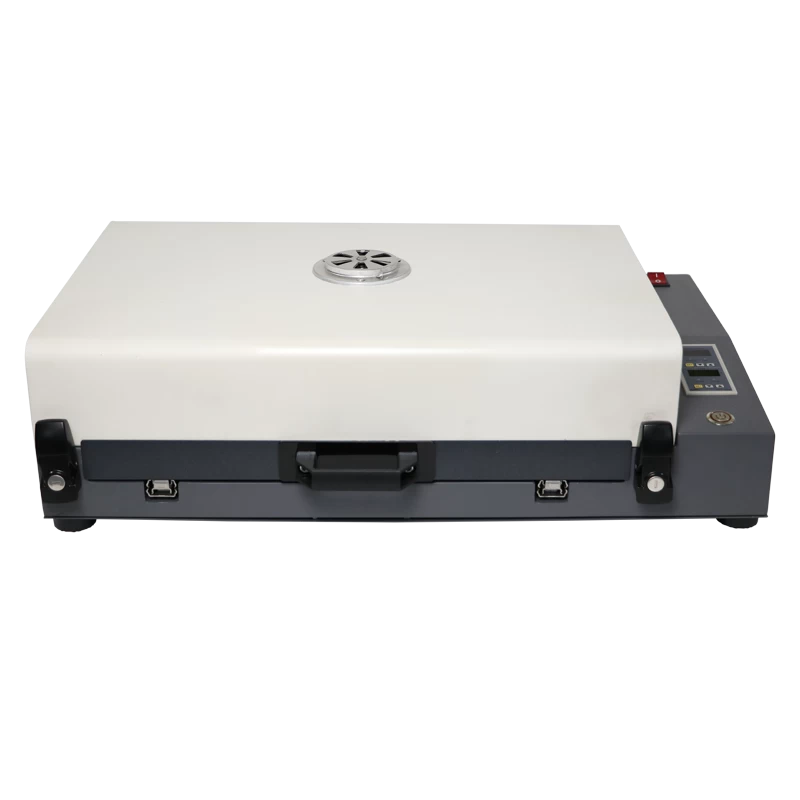

A3 DTF Oven For DTF Printing System

- Model No.: KX-300

- Setting temperature:110-150℃

- Machine Type: Manual

- Max. paper size: 33*47cm(Put in the heating plate)

- Controller: NTTF-2421WR Digital Time & Temp. Control

- Voltage: 120V/ 220V

- Power: 1600-2000W

- Time Range: 0-999 sec.

- Maximum Temp: 225℃

- Temperature Accuracy: ±5℃

|

A3 desktop DTF oven is a compact and efficient oven specifically designed for curing or drying Direct to Film (DTF) prints.

The PET film drying oven powder dryer provides efficient and controlled drying of PET film after the powder coating process. With temperature control, even heat distribution, and safety features, it ensures high-quality, moisture-free films ready for further processing or application.

Drying Capability: The A3 DTF oven provides a controlled and consistent heat source for the purpose of curing the DTF prints. It ensures that the ink adheres properly to the substrate, resulting in vibrant colors and long-lasting prints.

Even Heat Distribution: The DTF film oven is designed to provide even heat distribution across the entire surface area of the prints. This helps to ensure uniform curing or drying, preventing any color variations or defects.

Adjustable Time Settings: A3 DTF curing oven have adjustable time settings that enable users to set the desired duration for the curing or drying process. This flexibility allows for customization based on specific materials and ink types.

Precise Temperature Control: The A3 DTF dryer features a temperature control system that allows users to set and maintain the desired curing or drying temperature for DTF prints. This ensures consistent and accurate results.

User-Friendly Interface: The A3 direct to film oven with a user-friendly control interface, making it easy to operate and adjust the settings.

|

||||||||||||||||||||||||||||||||||||